Advantages of using prepreg

- Easy to process

- Stable size, Easy to mould

- Resistant to temperature and aging

- Little unravel during transportation

Scope of application

- Manufacturing Fishing rods, tennis rackets, skate boards

- Aerospace industry

- Automobiles, yachts, Ships

- Construction reinforcement

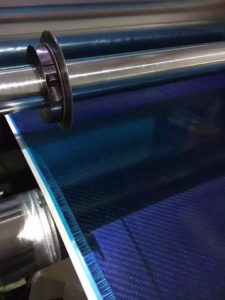

List of Woven Carbon Fiber Prepregs (Plain and Twill)

| dry weight | resin content | final weight | thickness |

| 3k 200 gsm | 40% | 330 gsm | 0.23mm |

| 6k 320 gsm | 40% | 535 gsm | 0.36mm |

| 12K 400 gsm | 45% | 725 gsm | 0.45mm |

| 12K 600 gsm | 40% | 980 gsm | 0.60mm |

List of Unidirectional Carbon Fiber Prepregs(UD)

| dry weight | resin content | final weight | thickness |

| 20 gsm | 50% | 40 gsm | 0.03mm |

| 30 gsm | 40% | 50 gsm | 0.05mm |

| 54 gsm | 38% | 78 gsm | 0.06mm |

| 75 gsm | 32% | 110 gsm | 0.075mm |

| 100 gsm | 35% | 155 gsm | 0.1mm |

| 150 gsm | 35% | 230 gsm | 0.15mm |

| 200 gsm | 35% | 300 gsm | 0.20mm |

| 300 gsm | 35% | 460 gsm | 0.35mm |

All these above UD prepregs can be produced with/without scrim.

For more information on the strength of these UD prepregs, please visit this link.

We also supply Carbon fiber prepregs of other weights than mentioned above. Resin Content can be varied based on clients’ requirements.

Methods of Curing

Our Prepregs are extremely convenient to work with and can be processed in a variety of methods:

- Autoclave

- Out of Autoclave

- Heat-press moulding

- Heat-shrink wrapped

Ideal curing process for our prepregs (made using TNYPH-42 resin)

- Once you take out the prepreg from the freezer, let it defrost overnight.

- For curing, first, cure it at about 80C for about 30 minutes

- Then raise to 120C, for 120 minutes.. If 130 C, only 60 minutes. About 4 hours if at 100 C

- Wait until the temperature lowers to 60 C , then remove mould

This is the process for our default/standard resin system, we also supply prepregs made using other epoxy resin systems with different Tg and curing temperatures.

Storage and Transportation

Our Prepregs can be stored at room temperature for about a month hence do not require freezer bags for transportation. But if stored in a freezer (at about -18°C) then our prepreg can last for more than 6 months.

We also supply Kevlar Prepreg and fiberglass prepreg

| List of Resin systems used in prepregs supplied by CA Composites | |||

| Resin

Name |

Glass Transition (Tg) | Curing Condition | Remarks |

| TNYPH-23 | 100-110 | 120 minutes at 90 C + 120 minutes at 100 C | standard resin/slightly lower curing temp |

| TNYPH-42 | 120-130 | 30 minutes at 80 C + 100-120 minutes at 120-125C | Standard tg/standard curing temp |

| JS-YPH170 | 175-180 | 30 minutes at 80 C + 90 minutes at 150 C | moderately high tg |

| TN-YPH170 | 170-190 | 30 minutes at 80 C + 45 minutes at 160 C | moderately high tg |

| JS-YPH200 | 195-205 | 30 minutes at 150 C + 120 minutes at 200 C (after cure) | highest Tg |

| TN-FR-Epoxy | 120-130 | 30 minutes at 80 C + 30 minutes at 150 C (or 90 minutes at 120 C) | Flame Retardant/ UL94 V-0 compliant |

| JS-FR-Epoxy | 120-130 | 30 minutes at 80 C + 90 minutes at 120 C | Flame Retardant/ UL94 V-0 compliant |

| JS-YPH150 | 140-150 | 5-10 minutes at 150 C | Superfast curing and moderately high tg |